Royal Purple

This page deals with Royal Purple branded oils

Introduction

Royal Purple High Performance has mediocre performance.

Legend

N/A = NO ADDITIVES

M# = SQUID INK ADDITIVE MIX VARIATION

C# = CUSTOM MIX, SEE UNDER CHARTS FOR MORE DETAILS

Results

High Performance 5W30

Recommended blend: M7 PLEASE READ BELOW FIRST.

SLR-3 Scoring ---

- N/A: 78.17

- M12: 79.09

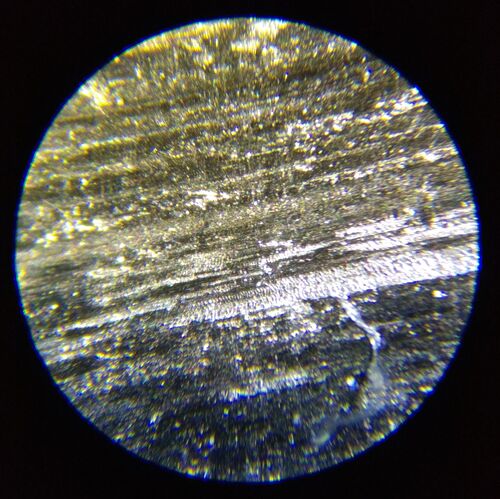

Additives seemed to do relatively little in comparison with other base oils, and even hurt in certain circumstances. While Royal Purple has fair 120 minute performance, it's initial performance was not ideal. It seems they add a color pigment to their oil to make it purple. They must assume that these pigments will be filtered out by the oil filter (this will cause near instant degradation of performance in the oil filter). There was no filtration in the wear tests performed. It's likely these pigments caused the poor initial performance. Planning to retest with an oil filtration system in place.

With M7 and M10: at the 60 minute mark there was a 20% reduction in cylinder weight loss, and a near 13% reduction in scar length. However, this was at the cost of more than 20'F increased temperature. Oil temperatures were within acceptable ranges.

- a secondary run with M6 was done reusing oil from the first test on new contact patch. This was to test how Royal Purple improves after burning off and removing the non-lubricating pigments. The 30 minute stress test shows that this oil improves after heat cycling and filtering for enough time. Other less expensive oils have better initial performance. There was a near 27% decrease in scar size during the 30 minute stress test using recycled, heat-cycled oil from the previous test.

The large number of non-lubricating additives in Royal Purple left noticeable and rather severe scarring on the surface of the cylinders.